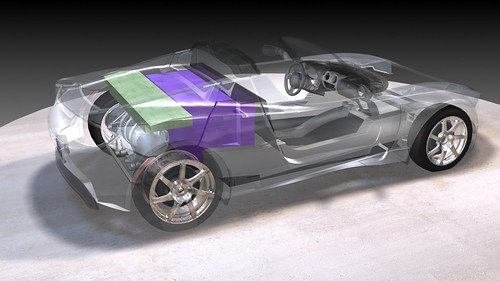

Electric cars require cooling systems. Not nearly to the extent that a combustion engine vehicle does, but lithium ion batteries get hot. Put your laptop on your lap for an hour and you might start cooking your own thighs. So you can imagine, thousands of lithium ion batteries will require a significant amount of cooling. There are 6,831 lithium-ion batteries in the Tesla Roadster, each about a third bigger than a typical AA battery. They’re linked together in a unique package that incorporates liquid cooling, safety fuses, and sensors that prevent the cells from experiencing what battery engineers like to call “thermal events.” The batteries feed 410 volts to the Roadster’s air-cooled AC induction motor. Here is the AC cooling system, for the cabin and battery pack:

Martin Eberhard, former CEO of Tesla Motors, is making the claim that the current cooling pump is working overtime, a lot of overtime. In, fact Eberhard stated that the pump for his Tesla Roadster seemed to be on all of the time, which is completely unnecessary after the car has been parked for an hour or so. Now the ESS cooling system is crucial to the life of the battery, but this is ridiculous. So, Martin Eberhard, being the electrical engineer that he is, installed one of those electric meters you see on the sides of houses ahead of his car’s charging station. Then he charged the car up fully, unplugged it for four days, then measured how much power it took to recharge the battery after the car sat, fully charged and cool, for four days. Doing some math, he found the car consumed 1,278 kWh per year, from just sitting there. That is enough to power two big refrigerators. Not only is this significant on your electrical bill, but this drastically reduces the lifespan of the pump. Eberhard explains in his blog post:

The second question is the life expectancy of the pump. I expect that Tesla used an automotive-grade pump from a good supplier. I am also sure that no other car leaves a pump running 24/7. Consider a typical car designed to run for 200,000 miles at an average speed of 30 mph. Such a car is designed to run for 200,000 / 30 = 6,666 hours. Let’s say the designers want some room for error, and design the water pump for that car to operate for 10,000 hours without failure. 10,000 hours life expectancy would be a good-quality automotive pump.

Now, let’s run that same pump 24/7 instead of the couple of hours per day it would run in our typical car. Running 24/7, that pump will pass 10,000 hours in only 13 months. That’s all – end of life. Just to make it through Tesla’s 3-year warranty, that pump would need to last 26,280 hours without failure. To last just 5 years, the pump would need to run 43,800 hours. Hopefully, Tesla installed a pump rated for at least 50,000 hours of operation without failure, implying an MTBF of at least 70,000 hours, assuming an exponential failure distribution. Does any automotive parts manufacturer even make such a pump?

Tesla also told Eberhard that the new Drivetrain 1.5, that they guarantee to retrofit all the purchased Tesla Roadsters with, will not make any changes to the pump. However, in a recent article from TIME, Elon Musk responded to Eberhard’s cooling pump complaints and also shed some light on the nature of their tumultuous business relationship:

Eberhard, the ousted cofounder, says Musk interfered with the design of the roadster, demanding changes that were costly and led to delays. These included installing electronic door latches, building a lightweight carbon-fiber body and lowering the doorsill by two inches. “It cost us $1.5 million to lower that doorsill,” Eberhard says. “We would have been better off to have a simpler car shipping a year earlier.” Musk says his design changes were not the cause of delays. Eberhard says that despite Tesla’s green-tech credentials, the roadster has a coolant pump that operates even when the car is parked, wasting as much electricity as two refrigerators. Musk says that will be fixed next month. Eberhard also gripes that Musk controls the board of directors, whose members include his brother Kimbal Musk. “I’m very unhappy about what’s happened to my company” under Elon, says Eberhard, who still owns about 3 percent of Tesla. “I think he’s a terrible CEO.” Elon Musk responds that “Martin is the worst individual I’ve ever had the displeasure of working with.” –TIME, An Electric Car Loses Its Juice

While Eberhard does have a legitimate complaint, keep in mind he probably takes some pleasure in publicly criticizing Elon Musk’s Roadster. But in the end, both sides just want to see the Roadster improved, and hopefully the issue can be fixed fairly easily and cheaply.